Smart Greenhouse Projects & Case Studies

Case Studies

What are some of the results grow operations have seen from integrating smart sensors into their greenhouse operations?

Lighting

South Mountain MicroFARM

Maryland, USA (7500 Sq ft Greenhouse)

Crop: Lettuce and Microgreens

Product supplier: LumiGrow LEDs

Key Stats:

- Lettuce crop reached harvest size in 40-50 days, shaving up to 33% off the crop production cycle. This allows Levi to fit in more turns.

- Microgreens were ready to harvest 2-3 days earlier than his unlit microgreens and produced approximately 10% more material per tray.

- Experimented with allowing the heads of lettuce to grow for the full 55-60 days and found the lit lettuce was 40-60% heavier. (Restaurants buy lettuce by the tote, so heavier heads allowed them to hit the tote weight with fewer heads of lettuce)

Green Mountain

Vermont, USA (11,000 Sq ft greenhouse)

Crop: Basil, Crisp Lettuce, Watercress

Products: Heliospectra

Key Stats:

- 50% reduction in the yellowing on the bottom lettuce leaves because the lights penetrate down deeper into the canopy.

- Heavier and more consistent weights.

- Trimmed off between 3-10 days on harvest cycle.

- Product height decreased which resulted in smaller packaging and lower packaging costs.

- Could run LEDs at night during lower electricity rates where HPSs would cause neighbor complaints from light pollution.

Lower Shannon Farms

Saskatchewan, Canada

Crop: Tomatoes and Cucumbers

Products: LumiGrow

Key Stats:

- Yield increase of 16-17% increase in his mini Dijon cucumbers and a 18-20% increase in his tomato crops’ yield

- “We’ve also easily added a month, 6 weeks of longevity to our [tomato] vines. Normally we’d take old vines out in February- we only started changing out first week of March.”

- leaves are about 20% bigger than they were under the 1000-watt HPS lights.

Smart LED Greenhouse Lighting

Looking for more information on how adding connected lighting to your greenhouse can impact yield?

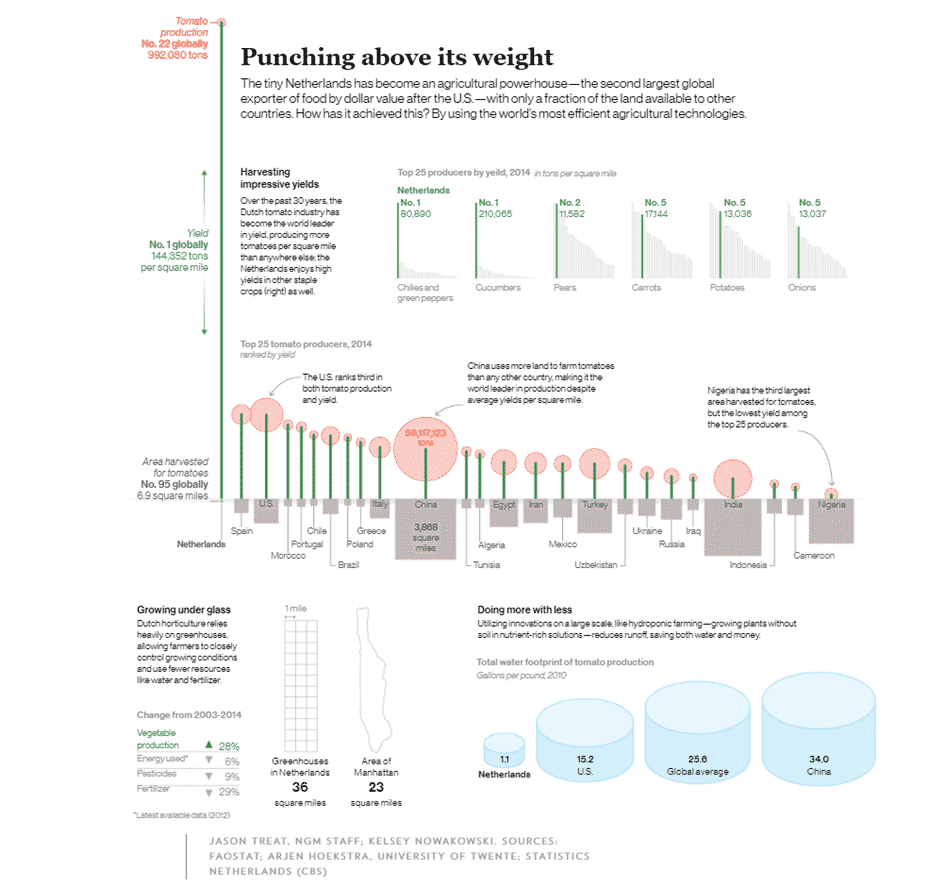

Dutch Tomato Production

The Dutch are the #2 exporter of food globally (only behind the US) They are by far and away the leading exporter of tomatoes as well as potatoes and onions. More than a 1/3 of all vegetable seeds global trade comes from the Netherlands. (Source)

From 2003-2014 their vegetable production:

- Increased by 28%

- Energy use declined by 6%

- Pesticide use decreased 9%

- Fertilizer use declined by 29%

General

- Microclimate Prediction for Dynamic Greenhouse Climate Control

- Simulations showed that controlling greenhouse temperature according to the predicted crop temperature rather than according to the air temperature can save energy. Energy-saving is highest during winter and 12% energy saving was attained during January under Danish climate conditions. - Analysis and design of greenhouse temperature control using adaptive neuro-fuzzy inference system

- Smart frost control in greenhouses by neural networks models

- Evaluation of event-based irrigation system control scheme for tomato crops in greenhouses

Operating Farms

Here is a list of companies using smart control technologies in their farm operations